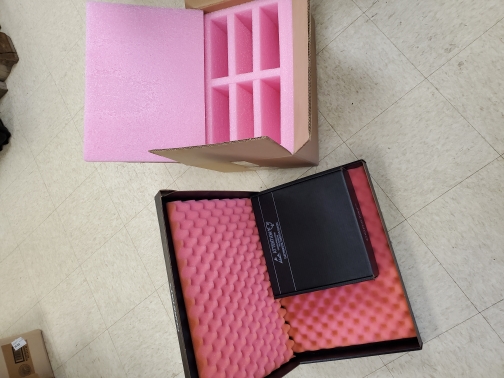

Custom ESD Anti-Static Packaging

At Quality Support, high-quality packaging solutions are important to us in meeting the specific needs of your business. We provide strong, durable, and dependable products for electronic components to prevent any electrostatic discharge from happening. Electrostatic discharge (ESD) can instantly damage electronic components and cause latent failures; that’s why it’s important for people working with electronics to protect devices and other components from ESD. Even though this is a well-known problem, industry experts with the ESD Association estimate that somewhere between 8% and 33% of products are lost due to ESD. The majority of these losses are entirely preventable with proper storage and handling.

Using ESD-rated, anti-static storage solutions and other ESD preventative measures may cost a little upfront, but it will save you in the long run. Read on for more information about packaging and other tools to protect your work and expensive devices from ESD in this handy guide.

Industry Standards for ESD Packaging

Look for any of the following industry standards when purchasing anti-static protective equipment — depending on your needs, your ESD protective equipment should meet these standards.- ANSI/ESD STM11.11 – Recommends the surface resistance of storage materials be between 106 and 109 ohms

- MIL-STD 3010 – Sets the testing standards for package durability, including thickness and puncture-ability

- ASTM F1249 – Denotes the standard test method to detect water vapor transmission

- FTMS 101C/4046 – Is the standard testing method for detecting the amount of corrosion a material will undergo

ESD Deterrent Bags and Pouches

ESD deterrent bags and pouches are the most common ways to protect devices from ESD. The type of bag you need will depend on what you are using it for and how you plan to transport the bag and object inside in the future. When selecting bags and pouches, consider the following:

- What is going inside the bag? What are the dimensions? Is it fragile, and is it sharp enough to damage the bag?

- Is moisture a concern?

- Do you need bags that self-seal?

- Where will you be storing the bags and items inside?

With this information ready, you will be able to determine which of the six common types of ESD bags and pouches will best fit your needs.

ESD Metal-In Shielding Bags

These bags have a metal layer (typically aluminum) in between two layers of plastic that creates a Faraday cage that protects the contents within the bag when the material meets a charge. The plastic layer on the outside is designed to dissipate static encountered in the environment. They come in many sizes and are most commonly used for PCBs for their level of protection and durability. These types of bags have a metallic sheen and are see-through.

ESD Metal-Out Shielding Bags

These bags are similar to the metal-in type; only the metal layer is on the outside of the bag. In this situation, the metal rapidly discharges any static, instantly repelling it from the bag’s contents, and you cannot see through them. This bag type may not be suitable for RF field-sensitive items.

ESD Moisture Barrier Bags (MBB Type)

MBB, or moisture barrier bags, offer ESD protection in conjunction with moisture protection. Labs or workshops in high-humidity environments should consider these bags for storing devices. The high and low barrier characterization refers to the amount of moisture control the bag provides. You can also purchase humidity indicator cards to help you determine if your environment requires these types of bags and to help you know when it’s time to refresh your bags.

ESD Bubble Shielding or Cushioned Bags

These bags offer faraday cage-induced protection and physical protection from damage upon impact in the way bubble wrap does.

ESD Conductive Black Bags

These bags contain low-density compounds and a black conductive compound to make a durable ESD-reflecting material, most often used for shipping and longer-term storage.

Once your bags arrive, it’s important to test them. Sometimes bags can arrive compromised. It’s also a great idea to mark your bags with electrostatic awareness labels so that people know to handle the bags with care.

Sealing Your Bags

You can buy self-sealing bags or bags that you must seal on your own. To seal bags, you can use ESD protective tape or a heat sealer for bags that allow it. Heat sealers are used in many industries and, in this case, are not much different from something you would find in food production; they can also come with and without cutting mechanisms. When sealing bags with components, ensure ample room to fold the bag material over and seal it without damaging the contents. About 50 extra mm of material is recommended for his process.

Handling ESD Components

Care also needs to be addressed when handling ESD components. This will include and as a minimum: antistatic bench mats, antistatic clothing, grounding by a wristband, anti-static mats, or other similar methods, ESD gloves or ESD finger cots, and component protective items.

ESD Packaging Gallery

View Full Product GalleryProviding high quality packaging that satisfies the most challenging specifications is our core strength. Our services are routinely used by major companies in industries that demand an elevated level of performance from their corrugated packaging vendor. We have an impressive track record for on-time delivery and give each project the personalized attention that it deserves. Contact us today to learn more.

Corrugated Packaging Details

- Made to Customer Specification/Military Specification

- Electrostatic

- Mil-B-81705

- Polyurethane

- Polyethylene

- PPP-C-1752

- A-A-59136

- Cross Link PE#2

- Colors

- Graphic Designs

- Auto-Lock Bottom

- UV Coating

- Film Laminate

- Wax

- Assembly

- Tipping Services (combining 2 products together as an offer)

- Package Design

- Component Sourcing

- Warehousing

- Distribution

- Screen Printing

- Drop Shipping

- Thermal Transfer Printing

- Bar Coding

- Labeling

- Lot Inspection

- Rework/Redesign Services

- Small Runs

- Large Runs

- Quoted on job-by-job basis

- Emergency services available

- Rush services available

- Defense

- Commercial Products

- Oil and Gas

- Solar Products

- Aerospace

- Automotive

- Electronic Components

- Military

- Semiconductor Equipment

- Architectural

- Construction

- Nuclear

- Mil-I-45208

- NQA-1

- MIL-STD-2073

- ASTM-D3951

- Vibration Testing

- Shock Testing

- Compression Testing

- Atmospheric Testing

- Burst Testing

- Shelf Life/ Real Time Aging Testing

- Accelerated Aging Test

- ASTM D4169 - Standard Practice for Performance Testing of Shipping Containers and Systems

- ASTM D4728 - Standard Test Method for Random Vibration Testing of Shipping Containers

- ASTM D3580 - Standard Test Methods for Vibration (Vertical Linear Motion) Test of Products